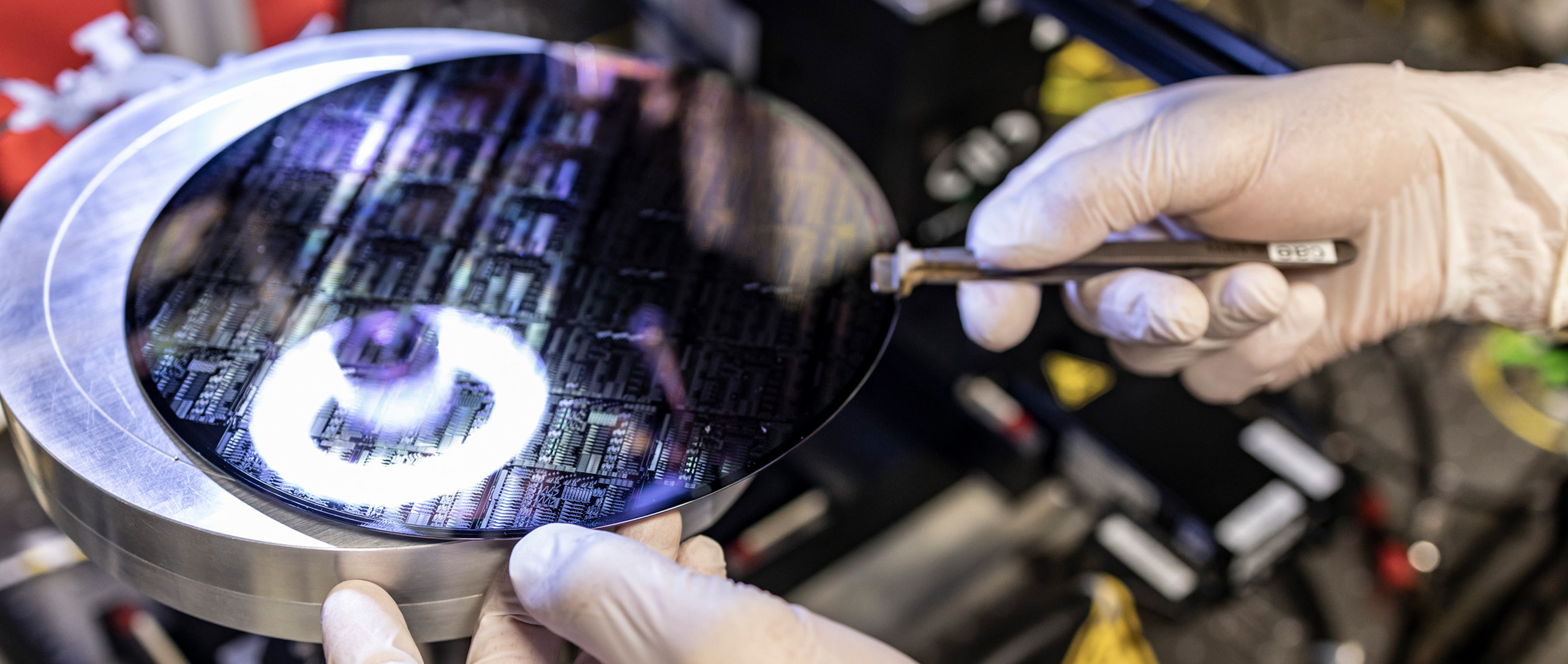

Wafer-thin crystals

Lithium niobate crystals are a well-known solution for electro-optic modulation in transceivers. These have been used for decades in optical modulators for long transmission distances such as Transatlantic links. They exploit the fast electro-optical Pockels effect. However, the components are several centimeters in size, and their specialized fabrication process makes them expensive to produce and impossible to scale to the necessary quantities of many millions of transceivers.